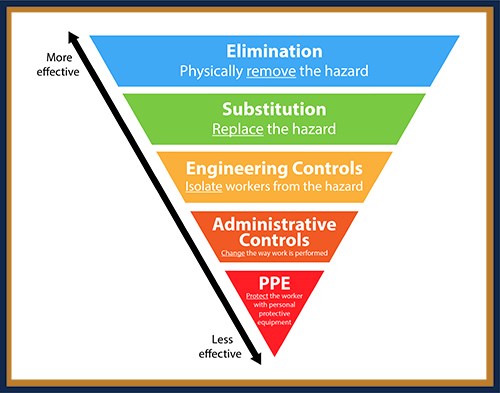

Hierarchy of Ergonomic Controls

When determining how to control ergonomic hazards, make sure to utilize the hierarchy of controls to develop as many solutions as possible. The hierarchy of controls as it relates to ergonomics is as follows:

Engineering Controls – these are changes made to processes, workstations, tools, and equipment that eliminate or reduce ergonomic hazards. The best engineering control is elimination—removing the hazard by removing the human interaction (e.g. automation). The next best engineering control is substitution—controlling the hazard by replacing the equipment or tool with something that has less ergonomic hazards and better fits the individual.

Work Practice Controls – these focus on changing how the individual performs the job tasks and deal with biomechanics and movement techniques. Work practice controls do not eliminate ergonomic hazards and successfully implementing these requires effective training coupled with an active observation and feedback system (e.g. behavior-based safety).

Administrative Controls – these regulate exposure to ergonomic hazards without making physical changes to the work area, equipment, tools or work process. Examples include job rotation, job task enlargement, and increased break schedules.

Personal Protective Equipment – this is not as effective at controlling ergonomic hazards. However, there are forms of PPE which can make individuals more comfortable while working (e.g. kneepads and anti-fatigue matting).

Coming up with fixes to address ergonomic hazards is sometimes difficult. Here at Atlas we have board- certified ergonomists on staff that can help you develop and test solutions that will work.